-

Building A-D, Huixianda Science and Technology Park, Wanfeng Middle Road, Shajing Street, Bao'an District, Shenzhen, China.

How to Mass Produce Vinyl Toys

The Big Problem: Making Many Vinyl Toys is Hard and Costly

You have a great vinyl toy design. You want to make many of them. But you face big problems:

- High costs for molds ($3,000-$5,000 for small toys)

- Long wait times (8-12 weeks for full production)

- Hard to find good factories

- Quality issues with cheap manufacturers

- Minimum order rules that are too big for small creators

This is why 7 out of 10 toy projects fail before they reach stores. Your great design stays just an idea.

Table of Contents

Why This Hurts Your Business

When you can’t mass produce your vinyl toys, you lose in many ways:

- Lost sales – the $18.58 billion art toy market grows without you

- Angry fans who want your toys but can’t get them

- Big companies take your ideas and make them first

- Money wasted on bad prototypes and failed attempts

- Time lost trying to fix production problems yourself

Each day without action, the gap between your design and store shelves grows wider.

The Solution: Partner with a Model Factory for OEM and Wholesale

As a professional model factory specializing in vinyl toy production, we solve all these problems. We handle the full production chain:

- Design optimization for mass production

- High-quality mold making at fair prices

- Material selection including eco-friendly options

- Production line setup for consistent quality

- Packaging and shipping to your customers

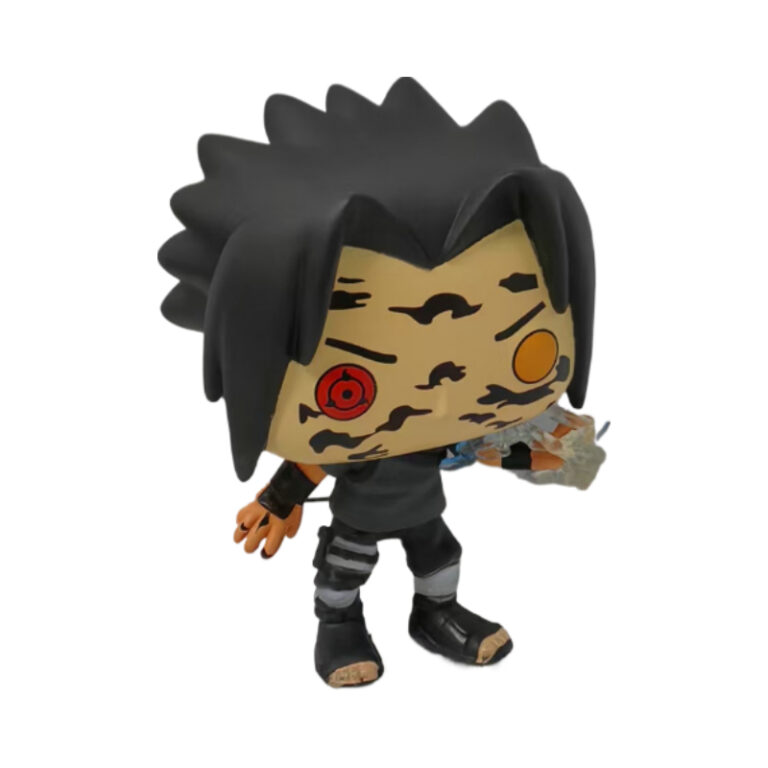

Our Funko Action Figures show the quality we deliver to big brands and small creators alike.

The Market Is Ready for Your Toys

Look at these numbers:

| Market Fact | What It Means for You |

|---|---|

| Global toy market: $324.66 billion (2023) | Big pool of buyers ready for your designs |

| Art toy market: $18.58 billion by 2025 | Special spot for unique vinyl toys growing fast |

| 5.3% yearly growth in art toys | More sales each year for good designs |

| US market: $29.8 billion (2024) | Huge market just in America |

| Online sales: 42% of all toy sales | Easy to reach buyers worldwide |

The toy world wants new, cool designs right now!

How We Make Your Vinyl Toys: Step by Step

1. Design and Prototype Help

Problem: Most toy designs aren’t ready for mass production.

We fix this by:

- Making your design factory-ready

- Using 3D printing for fast prototypes

- Testing all moving parts

- Finding ways to cut costs

Our team has made Five Nights at Freddy’s Action Figures and knows what works.

2. Mold Making That Saves Money

Problem: Molds cost $3,000-$5,000 and often have problems.

We fix this by:

- Using strong steel or aluminum molds that last

- Making multi-cavity molds to produce more toys at once

- Testing molds before full production

- Fixing mold issues fast when they happen

Good molds mean good toys and less waste of your money.

3. Material Choice for Today’s Market

Problem: Buyers want eco-friendly toys but they must look and feel good.

We fix this by:

- Offering regular vinyl and eco-friendly PVC

- Making soft vinyl (Sofubi) like Japanese collectors love

- Ensuring all materials pass safety tests

- Matching colors perfectly every time

In 2025, 35% of buyers will pay more for green toys – we help you reach them.

4. Production That Scales With You

Problem: Most factories want huge orders or charge too much for small ones.

We fix this by:

- Starting at 1000 pieces (not 5,000 like others)

- Offering better prices as you grow

- Running quality checks on every batch

- Fixing problems before toys ship

Our production line makes everything from Action Figures to art toys with the same care.

5. Full Support After Production

Problem: Many factories disappear once they ship your order.

We fix this by:

- Packaging design that sells

- Warehouse space if you need it

- Shipping help to stores or fans

- Fast fixes if any problems come up

We stay with you from idea to happy customers.

Why Mass Production Fails Without Expert Help

Look at these common issues:

- Bad molds (70% of delays come from mold problems)

- Poor material mix (toys look wrong or break)

- Color matching issues (toys don’t match your design)

- Packaging damage (great toys ruined in shipping)

- Missing safety tests (can’t sell in some countries)

Each problem costs time and money. Our factory stops these problems before they start.

Success Stories: Toys We Helped Make

Case Study 1: Art Toy Startup

- Before: Great design, no way to make more than 10 toys

- Our help: Made molds, suggested material changes, set up production

- Result: 1,000 toys sold in first month, now making 5,000 per run

Case Study 2: Toy Shop House Brand

- Before: Buying toys from others, wanted their own line

- Our help: Full production from design to store-ready toys

- Result: 40% higher profits, full control of quality

Case Study 3: Kickstarter Campaign

- Before: Raised money but couldn’t find a good factory

- Our help: Fixed design issues, made production plan, delivered on time

- Result: Happy backers, successful second campaign

Cost Breakdown: What to Expect

| Item | Cost Range | What Affects Price |

|---|---|---|

| Mold making | $3,000-$5,000 | Size, detail level, number of parts |

| Materials | $1-$5 per toy | Type of vinyl, color effects, softness |

| Labor | $0.50-$3 per toy | Painting detail, assembly needs |

| Packaging | $0.20-$2 per toy | Box type, insert quality, printing |

| Shipping | Varies | Weight, speed needed, destination |

We help find ways to save money without hurting quality.

Market Trends to Use in Your Toy Design

The toy world changes fast. Here’s what’s hot:

- Eco-friendly materials growing 19% by 2025

- IP partnerships (41% of art toy sales)

- Blind box toys (60% of online sales)

- Collector editions with special features

- Tech integration like QR codes or app links

We help your toys match these trends to sell more.

How to Start Your Vinyl Toy Production

Step 1: Contact Us With Your Design

Send us:

- Design files or sketches

- Size and feature needs

- How many toys you want to make

- When you need them done

Step 2: Get Your Free Production Plan

We’ll make a plan showing:

- Timeline for each step

- Cost breakdown

- Material options

- Ways to save money

Step 3: Start Small and Grow

Begin with a smaller run to test the market. As sales grow, we scale up production while:

- Lowering costs per toy

- Improving features

- Adding new designs to your line

Why Choose Our Factory?

- 10+ years making toys for big and small brands

- In-house mold shop (no sending out for fixes)

- All safety certifications for global sales

- Fair pricing that scales with your growth

- English-speaking team for easy talks

Questions Toy Makers Ask Us

How many toys do I need to order?

We start at 1000 pieces. Most factories want 2,000+.

How long does it take?

From design to finished toys: 8-12 weeks for first run, faster after that.

Can you copy this toy I like?

No. We only make original designs to avoid legal issues.

Do you help with toy safety testing?

Yes! All our toys meet US and EU safety rules.

Can I visit the factory?

Yes, we welcome visits to see your toys being made.

Ready to Make Your Vinyl Toys?

The $18.58 billion art toy market is waiting for your designs. But without good manufacturing, your ideas stay just ideas.

Don’t let production problems stop your success.

As your manufacturing partner, we turn your vinyl toy designs into ready-to-sell products. From molds to materials to mass production, we handle the hard parts so you can focus on creating and selling.

Contact us today for your free production plan and cost estimate.

About Us: We are a full-service toy manufacturing factory specializing in vinyl toys, action figures, and collectibles. Our services include design help, mold making, material sourcing, production, packaging, and shipping. We work with brands of all sizes to bring their toy ideas to life.

![Funko POP! Marvel Loki Exclusive Vinyl Figure #615 [Mjolnir]](https://figurinesmanufacturer.com/wp-content/uploads/2025/02/微信图片_20250221135410.png)